Summary of Provincial Budgets 2024: Ontario & Quebec

Provincial governments are slowly unveiling their provincial budgets outlining fiscal strategies ...

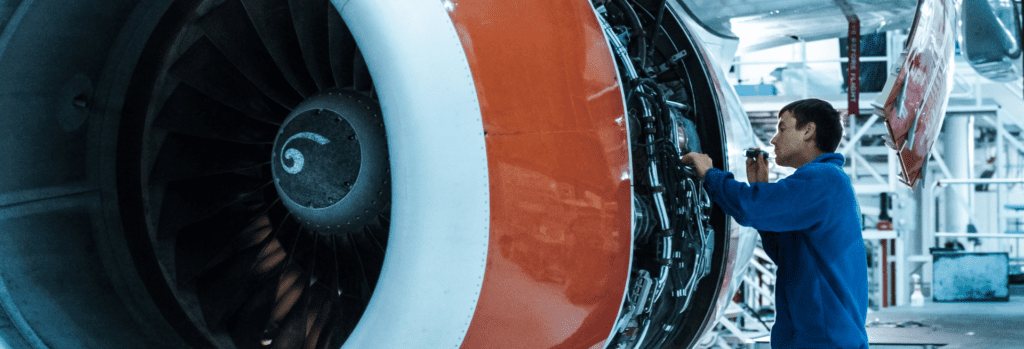

The fuel consumption of an aircraft largely depends on its mass. It has been shown that a weight reduction of 500 kg translates into a reduction of around 1% in fuel consumption. The aeronautical industry is currently working on the design and the development of new materials that are lighter than those already existing in order to reduce the weight of parts and components and allow planes to fly higher and faster while consuming less fuel.

3D printing: a promising technology

To succeed in this bet, 3D printing is proving to be a very promising technology for the aeronautics industry, both economically and in terms of manufacturing. In fact, on the one hand it allows the elimination of the usual processes which consume a lot of material resulting in manufacturing time savings and on the other hand a design of lighter parts resulting in a gain in weight and consequently better performance in flight.

The manufacture of these 3D parts is based on the use of additives, which are added layer by layer in the printing process to produce the object close to its final shape. The combination of additive (AM) and generally aluminum alloy (AA) is essential for the manufacture of lightweight components.

The proven combination of AM and AA is often limited to a few alloys eg AlSi12 and AlSi10Mg. For non-structural parts, there is a lack of knowledge about the whole AM metallurgy of aluminum alloys especially A3xx series (2). This lack of knowledge in microstructure, mechanical properties and behavior during manufacturing and in service must be overcame before mainstreaming AM as a viable manufacturing solution and industrial adoption of its components.

The aerospace industry has entered a very active research and development phase in order to fill this lack of knowledge with regard to the AMs of these alloys and integrate these fundamental data into their respective design and manufacturing operations. This is a considerable challenge for 3D printing technology because of the mechanical characteristics of the materials that are required in the manufacture of aerospace components.

Currently, research works have reached very interesting results, with regard to the characterization of the microstructure-treatment-properties relationships for the AM of AA. This combination has already shown significant weight savings compared to non-structural cast components such as those in aircraft engines (2). These results open up great potential to contribute to overall engine weight reduction and ultimately better aircraft in-flight performance.

Wish to benefit from the support of our experts for your innovation projects in aeronautics?

Sources :

Explore our latest insights

More arrow_forward

Provincial governments are slowly unveiling their provincial budgets outlining fiscal strategies ...

Recently, Canadian representatives attended COP27 to discuss the actionable steps to implement to...

Human-Machine Collaboration has become an essential part of the manufacturing industry. This coll...

Recent announcements demonstrate that the SR&ED program is now under review. The government w...